Lockout Tagout Training in Canada

The Benefits of Lockout Tagout Training in Canada

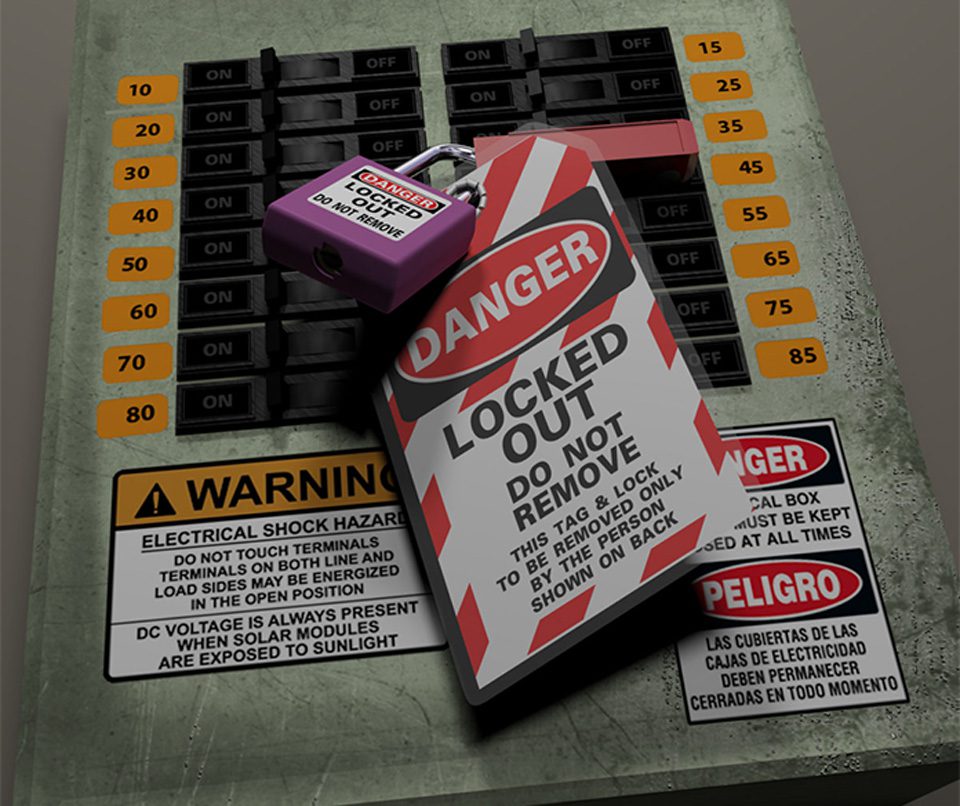

Lockout Tagout (LOTO) is a crucial safety procedure used to protect workers from the release of hazardous energy during maintenance or servicing of equipment and machinery. In Canada, LOTO training is an essential component of workplace safety across various industries, including manufacturing, construction, and maintenance. This training is designed to educate workers on the proper methods of isolating energy sources, applying locks and tags, and ensuring equipment remains inoperative during maintenance activities. In this article, we will explore the numerous benefits of Lockout Tagout training in Canada and how it contributes to creating a safer work environment and protecting workers from accidents.

- Reduction in Workplace Accidents

The primary benefit of Lockout Tagout training is the substantial reduction in workplace accidents. Failure to properly isolate energy sources before maintenance can result in unexpected machinery activation, leading to severe injuries or even fatalities. LOTO training equips workers with the knowledge and skills needed to safely de-energize equipment, significantly reducing the risk of accidents.

- Compliance with Canadian Regulations

Canada has stringent workplace safety regulations in place, and compliance with LOTO procedures is mandatory. Failing to adhere to these regulations can result in legal consequences, fines, and work stoppages. LOTO training programs are designed to ensure that workers understand and comply with Canadian safety standards, helping organizations remain compliant with safety requirements.

- Enhanced Hazard Recognition

LOTO training emphasizes the importance of hazard recognition. Workers learn how to identify potential dangers associated with machinery and equipment, as well as the energy sources that power them. This proactive approach enables employees to anticipate risks and take preventive measures, ultimately minimizing the likelihood of accidents and injuries.

- Improved Safety Culture

Implementing LOTO training fosters a culture of safety within the organization. When employers invest in the education and training of their workers, it sends a clear message that safety is a top priority. Employees are more inclined to adopt safe practices, report potential hazards, and encourage their colleagues to do the same, creating a safer work environment and promoting safety as a shared value.

- Customized Training

LOTO training can be customized to address specific workplace needs and challenges. Organizations can tailor the training to account for unique factors, such as the types of machinery used, the complexity of energy isolation procedures, and industry-specific regulations. Customized training ensures that workers are well-prepared for their specific job requirements, reducing the likelihood of accidents related to their specific tasks.

- Increased Efficiency

Well-trained workers can perform maintenance and servicing tasks more efficiently. They understand how to properly isolate energy sources, apply locks and tags, and follow established procedures, allowing them to complete their work more quickly and accurately. Increased efficiency not only boosts workplace productivity but also reduces the time spent exposed to potential safety hazards.

- Emergency Response Preparedness

LOTO training includes instruction on emergency response procedures. Workers learn how to react effectively in critical situations, such as equipment malfunctions or the discovery of a coworker in a dangerous situation. Being prepared for emergencies minimizes their impact and ensures a timely and effective response, which can be crucial in mitigating potential accidents and injuries.

- Reduction in Workers’ Compensation Claims

Proper LOTO training can lead to a reduction in workers’ compensation claims. When employees are well-prepared and educated on safety practices, they are less likely to sustain injuries on the job. Fewer workplace injuries mean fewer claims, which can lead to lower insurance premiums and cost savings for employers.

- Boosted Worker Morale

Employees who receive LOTO training are more likely to feel valued and cared for by their employers. This can boost morale and job satisfaction among workers, leading to higher retention rates and increased loyalty to the organization. A happy and satisfied workforce is more likely to adhere to safety guidelines and contribute to a safer work environment.

- Prevention of Equipment Damage

LOTO training not only protects workers but also prevents damage to machinery and equipment. Accidental activation of machinery during maintenance can lead to costly repairs or replacements. Properly implemented LOTO procedures ensure that equipment remains inoperative during servicing, reducing the risk of damage and associated expenses.

Lockout Tagout training is an indispensable component of workplace safety in Canada. By reducing the risk of accidents and injuries, ensuring compliance with regulations, enhancing hazard recognition, and promoting a safety culture, it significantly contributes to creating a safer work environment and protecting workers from accidents. Moreover, it equips employees with the knowledge and skills needed to properly isolate energy sources and ensure equipment remains inoperative during maintenance activities.

Investing in Lockout Tagout training is not only a legal requirement but also a crucial step in safeguarding the well-being of workers and ensuring the overall success of maintenance and servicing tasks. It is an investment in both safety and efficiency, ultimately benefiting the organization as a whole. Workers who prioritize LOTO compliance through proper training not only protect themselves but also set a positive example for others, creating a safer work culture for everyone to thrive in.

Click here for an online lockout tagout course.

Click here for Government of Canada information.